© 2017-2019 Kunshan Feiya Precision Moulding Co., Ltd. All rights reserved. Site Map Designed by Alibaba

Metal stamping die is one of tooling and parts service from FEIYA, we are looking for more and more business partners in a long time cooperation, since we recived many customer visits from all around the world, we have much experience on progressive stamping die toolmaking and manufacturing.

Years ago, 3D printing technology world engulfed like tornado, FEIYA is a traditional plastic injection molding manufacturer, business includes: plastic injection molding, progressive stamping die,cnc machining parts and all molding parts can be customized according to requests. althoughthe advanced technology always gets more and more attentions and popular, but it is still in unmature stage, people will choose stamping die depends on its precision and reliable stable quality.

Then you confused about how is the difference between 3D printing and tooling making?

Difference concept:

3D printing technology or additive manufacturing is a process of making three dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created.

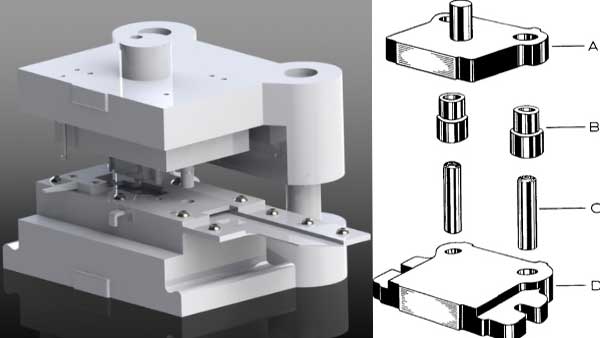

Tool and die makers are a class of machinists in the manufacturing industries who make jigs, fixtures, dies, molds, machine tools, cutting tools, gauges, and other tools used in manufacturing processes. Depending on which area of concentration a particular person works in, he or she may be called by variations on the name, including tool maker (toolmaker), die maker (diemaker), mold maker (moldmaker), tool fitter (toolfitter), etc.

Different development orients:

A. Tool making is invented to achieve large volume and in low cost. it is still main various industry parts manufacturing ways. plastic injection molded parts and progressive stamping metal die parts.

B. 3D printing technology is still in low volume production and now made affordable. the cost for 3D printing is high then average part made by toolmaking. for example, it is not the optical choice for a auto manufaturer to choose 3d printing technology for large scale diverse plastic parts and metal, brass metal stamping die parts supplies, it will result in high cost to a car.

Difference of precision:

a. 3D printing making parts precision is almost same with the tooling making parts, the advantages of 3D printing technology is easy to operate. simplified the parts making processes.

b. Traditional stamping die aluminum parts making will experience dozens of times to ensure the precision in ±0.002.

FEIYA is commmitted to offer quality parts to buyers in low price, it is certainly we will update the technology in near future for better development, we supplies different standard parts for multiple industries, like cellphone connectors, computer main board, auto abs shell and so on. we believe our progressive stamping die parts service can satisfy our customers.