© 2017-2019 Kunshan Feiya Precision Moulding Co., Ltd. All rights reserved. Site Map Designed by Alibaba

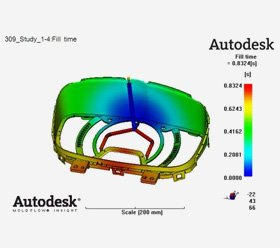

Building the plastic injection molding tool and progressive stamping die tool take time and a great deal of accuracy. It can be the largest investment in the manufacturing process, so paying more attention to this step will be the key to a project success. If your goal is to produce a part with a high degree of precision in large-volume, the mold becomes even more complex.

The Feiya mold manufacturing industry best mold, and our tool warranty reinforces our claim. As long as Feiya is running a tool that we have built, there will never be any repair or maintenance charges. We design high volume, high tolerance production tool for the long life of your project. Our tools are constructed from good quality mold bases and cavities ensuring optimal mold performance and durability.

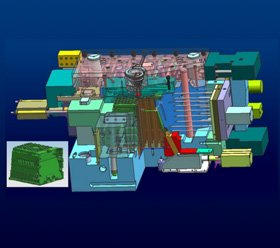

Building a high quality precision mold is an investment in your company. Several variables impact the cost of a plastic injection mould including:

High volume precision molds are made from hardened steel that can withstand the pressures of a long production run while still meeting close tolerances. At The Feiya mold, we have many plastic injection molds that have been in production for decades.

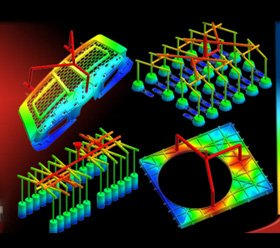

We hope to maximize cavities in the mold to maintain the highest level of productivity. In general, we recommend that each part to create one mold, instead of creating a family mold which tends to produce inferior products and has more downtime due to maintenance issues.

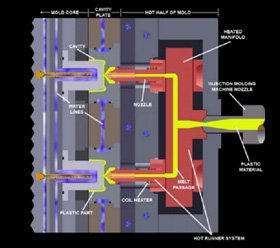

The tool base holds all of the mold cavities, cores, inserts and components together. The cost of the mould base is estimated based on the size of the mold and the type of steel material used to make the base as well as the customization required.

The core and cavity is the most important part of a mold. It be asked good steel material and high precision machining technology. All molds must be customized. Customization includes the placement of cores, cavities, ejectors, cooling lines, gate, runner system etc.

Just as the number of cavities plays a role in determining the cost of the mold, so does parts. This includes the surface finish of the final part as well as the number of undercuts required.

The cooperative efforts of our designers and tool makers to ensure quality, precision tolerances, and optimized cycle times of a mold.

There are a little different to build a progressive stamping dies with plastic injection mold. But it’s almost the same when you want to build a precision stamping tool.