© 2017-2019 Kunshan Feiya Precision Moulding Co., Ltd. All rights reserved. Site Map Designed by Alibaba

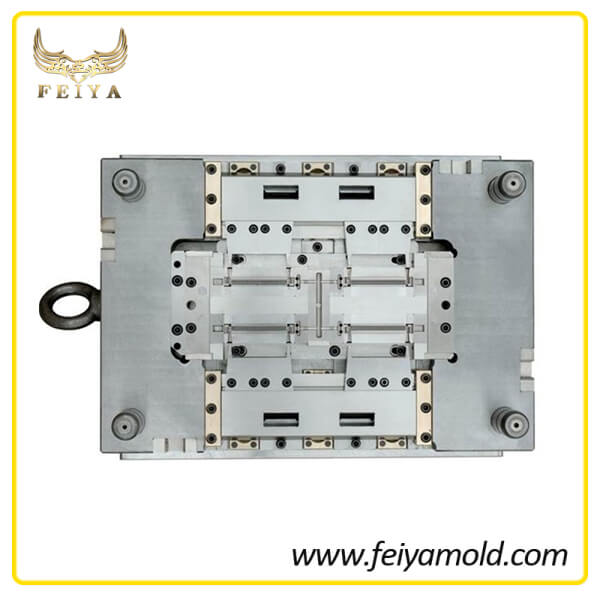

Process is called Die Stamping , Die Stamping is a widespread non-expendable technique the which metal are forced into the mold cavity under high pressure. Die casting mold that are known as industrialmetalcastings.comdies can be used repeatedly to produce castings in a variety of sizes, shapes and wall thickness. The mold cavities are designed with intricate designs that enables in producing complex shapes with accuracy,surface finish and attractiveness. Today, the die casting process is constantly getting refined by improving the alloys and the casting process.

Marc and Vortselas mention one method. Another method is Powdered Injection Molding, PIM . Here a finely divided powder(iron in many grades, SS, nickle, etc are mixed with a binder/flow aid, 90% by weight metal, which by volume varies considerably but around 50%. One version uses seaweed(agar), another wax. I have used PE, and one company even used PEI(polyether imide). This compound is then injection molded in conventional equipment, wearing the barrel and screw dramatically. The molded part is then cooled, or in the case of agar dried, before putting it in an over where the temperatures are staged first to boil off the polymer, then finally to sinter the metal. This process has developed over the last 25 years to where there are molding companies that only mold these materials. They are especially effective cost wise for very small, intricate parts that would be difficult to manufacture by any other method.