© 2017-2019 Kunshan Feiya Precision Moulding Co., Ltd. All rights reserved. Site Map Designed by Alibaba

Protolabs use a fast injection moulding technology-driven method that leverages producing automation. CAD models ar sent on to the assembly floor wherever mould edge begins, however in most cases, moulds ar unreal from aluminum, not steel. this enables for quicker and most efficient tooling when put next to ancient steel moulds.. we provide variety of further moulding and tooling services to support your project.

The thermoplastic injection molding method at Protolabs may be a customary method involving associate atomic number 13 mould with no heating or cooling lines running through it, which implies cycle times ar a trifle longer. It permits our moulders to observe fill pressure, cosmetic considerations, and also the basic quality of the elements.

Resin pellets loaded into a barrel wherever they're going to eventually be molten, compressed, and injected into the mould’s runner system. Hot organic compound is shot into the mould cavity through the gates and also the half is moulded. Ejector pins facilitate removal of the half from the mould wherever it falls into a loading bin. once the run is complete, elements (or the initial sample run) ar boxed and shipped shortly thenceforth. Request your Free style Cube that shows surface finishes and thick and skinny finishes.

We offer a spread of plastic injection molding services, together with insert molding, overmolding, second and 3D CAD modeling, unhearable attachment, and hot stamping. we provide style and engineering help, primarily in injection molding tooling, so as to assist you optimize your half styles for manufacturability, repeatability, and cost, likewise as scrutiny and internal control processes to confirm high-quality elements that meet the high standards of our customers and their individual industries.

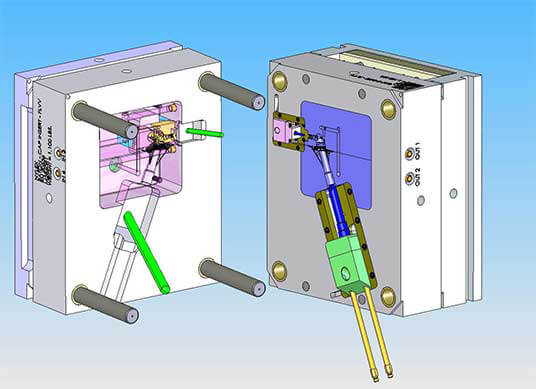

When we style our tooling for injection molding, our knowledgeable engineers use simulation techniques like Moldflow to confirm that the elements and materials are going to be shaped properly which our injection molding tooling utilizes the best gating to confirm most potency of the injection molding method.