© 2017-2019 Kunshan Feiya Precision Moulding Co., Ltd. All rights reserved. Site Map Designed by Alibaba

Feiya offers the fastest, most cost-effective, short run injection molding services available in the world. From start to finish we can ship most projects in 15 days or less.

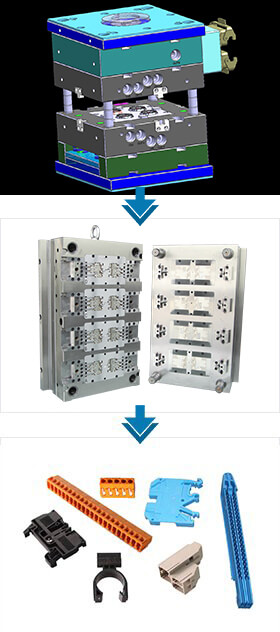

Our precision mold process performs incremental changes to the part as it passes each station and sends the completed part down a product chute for packaging at the end. We use highly advanced injection molding with capacities from 30 to 150 tons, achieving tolerances of ±.002. A wide range of materials such as PP, PBT, ABS, PVC, PE, PA etc.

Mold is mainly composed of pouring system, temperature control system, forming parts and structural components.

Our processing automotive interior plastic parts molds/ precision electronic digital plastic parts mold/ precision medical equipment parts mould/ all kinds of connector and terminal mould. (Mould spare parts tolerance within +/-0.002mm) can be customized design.

We have thousands of different types of available for you to choose from, for a wide range of mechanical and cosmetic properties.

Plastic injection molding manufacturing is great for larger volumes. For smaller volumes we might recommend other services like CNC machining.

Hundreds of thousands of parts can be produced from a single mold tool.

Your part can have excellent surface quality finishes in a wide range of polishes and textures.

Injection molding allows you to do overmolding to combine different types of plastic in one piece. It is ideal for lightweight parts that are immune to corrosion.