© 2017-2019 Kunshan Feiya Precision Moulding Co., Ltd. All rights reserved. Site Map Designed by Alibaba

The requirements of automobile production for plastic parts is getting higher. The accelerated speed of vehicle model development and the continuous reduction of costs have forced manufacturers of automobile plastic parts to continuously develop and adopt new production processes. Injection molding is the most important technology for producing plastic parts for automobiles.

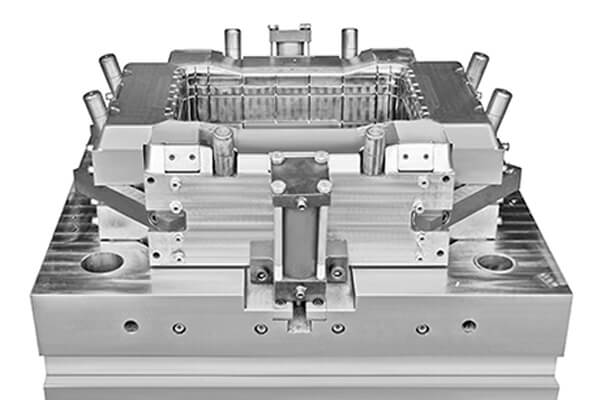

Due to the unique characteristics of plastic parts of automotive complex parts, the design of plastic injection mold for auto parts needs to fully consider the following factors: drying of the material, new requirements for glass fiber reinforced materials on the screw, driving form and mold clamping structure etc.

First, when the commonly used resin materials such as automobile bumpers and dashboards are modified resins such as modified PP and modified ABS, the resin materials have different hygroscopic properties. %). Before the resin raw material enters the screw pre-molding of the injection molding machine, it must be dried by hot air or dehumidified.

Second, domestic plastic parts for automobiles are basically non-glass fiber reinforced plastic products at present. Compared with the use of chopped glass fiber reinforced resins, the material and structure of the screw of the injection molding machine used for molding non glass fiber reinforced plastic parts has big difference. While doing automotive plastic injection molding, pay attention to the alloy material of the screw barrel and the special heat treatment process to ensure its corrosion resistance and strength.

Third, because the automotive parts are different from conventional products, its cavity surface is very complex, the forces are uneven and the stress distribution is uneven. The design needs to consider the processing capacity. The processing capacity of the injection molding machine is reflected in the clamping force and the injection molding capacity (represented by the maximum theoretical injection volume). When the injection molding machine is molding the product, the mold clamping force must be greater than the mold opening force generated by the mold cavity pressure, otherwise the mold parting surface will be separated to produce flash.

To ensure reliable mold clamping, the process clamping force during injection molding must be less than the rated clamping force of the injection molding machine. The maximum theoretical injection volume of an injection molding machine matches the tonnage of the injection molding machine. It is the injection capacity of the injection molding machine that is nominally based on polystyrene (PS) resin before it leaves the factory.