© 2017-2019 Kunshan Feiya Precision Moulding Co., Ltd. All rights reserved. Site Map Designed by Alibaba

At the moment the plastic is one of the most used materials in all the industries, because it is cheap, resistant and moldable, therefore, this adapts perfectly to the needs of packaging and packaging of any product.

To be able to manufacture products made from plastic it is necessary that it goes through different processes and machining, such as molding.

The plastic injection molding is an effective system for the manufacture of small and large pieces of plastic with an excellent quality and finish. For this, it is essential that the mold has the best qualities, precise processing and maximum durability. Within the steps in the manufacture of the molds, the most important is that of the plastic piece since it has to have a correct and effective design.

The objective of a plastic injection mold is the distribution of molten plastic, to take the correct shape, cooled and then eject the molded part. The distribution channels or castings must be balanced, so that the material travel is the same for the different cavities, that way we will obtain a balanced filling of all the cavities and a balanced pressurization of them.

For the correct design of an injection mold it is important to be clear about the following steps:

Design correctly the plane of the piece to inject, mark the lines of partition, zone of entrance of injection, position of the ejectors and any detail of the mold that can facilitate its correct manufacture. In this case you need to consider the progressive stamping die.

According to the specifications of the plastic to be used in the mold, it is necessary to take into account the shrinkage, characteristics of flow and abrasion, molecular structure, thermal behavior, viscosity.

To manufacture a mold and a piece of injection of precision, the main points to take into account are the dimensional accuracy with the required tolerances, the material to be used in the molding process and the final finish of the piece.

Plastics with low shrinkage present no problem when calculating their final dimension and the dimensions of the mold can be easily calculated to give the final accuracy of the product dimension. Plastics with high contraction should be taken with more consideration and study more critical points because it is more complicated when calculating your reaction.

For the manufacture of molds for the injection of plastics is required the use of special steels, due to the loads to which they are subjected.

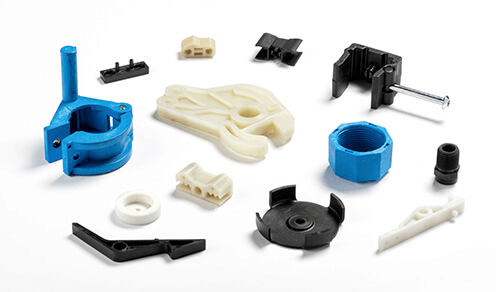

The products that can be manufactured from plastic injection molding are:

- Toys

- Furniture

- Automotive parts

- Bottles

- Feathers

- Buckets

- Topers

- Plastic boxes

- Boxes for sandwiches

- Lunchboxes

- Tapas

- Connectors

It is also applied in the production of high-quality CNC Machining Parts and sub-assemblies according to customer specifications.

The costs for the manufacture of the molds are usually high, since the times used in the mechanization and adjustment of these is usually considerable. In addition, the accuracy of dimensions and surface quality is often extremely laborious to achieve.

The final finish of the figure to be injected on many occasions is a very important aspect when deciding the finish of the mold. This factor is important for the correct behavior of the plastic and supposes an additional cost being one of the highest final costs in the construction of the molds.