© 2017-2019 Kunshan Feiya Precision Moulding Co., Ltd. All rights reserved. Site Map Designed by Alibaba

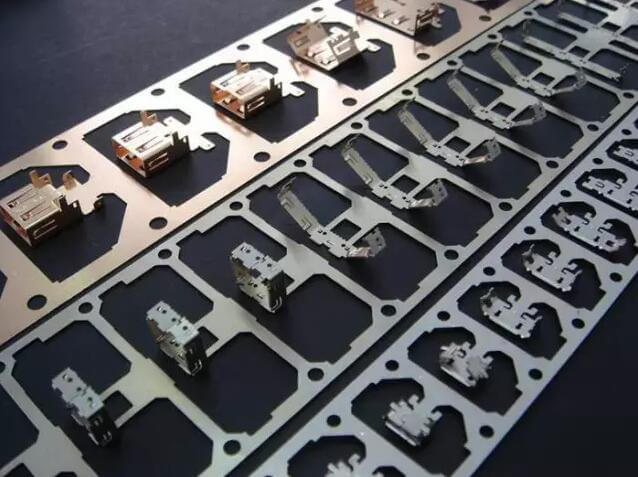

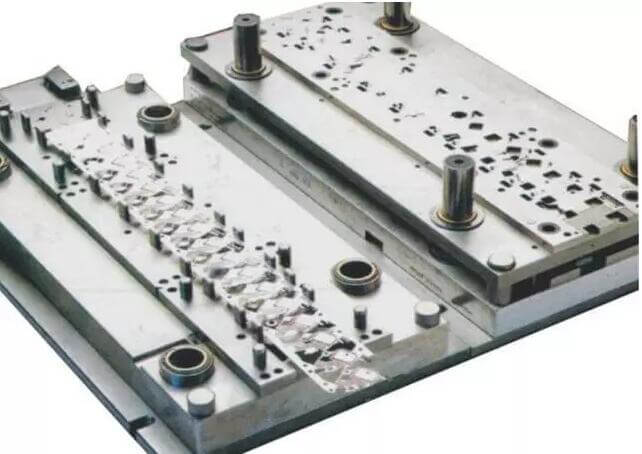

Stamping is one of the practical processes for mass production. In the stamping process, the mold has the most problems, it is the most important factor in the production of stamping factors. Directly affect the production efficiency and cost. Affecting the delivery cycle of the product. Mold problems are mainly concentrated in the mold damage, product quality defects and mold grinding, they long plagued the industry production. Only the correct handling of these key points. Stamping production can be carried out smoothly.

Mold failure is the most prone to the production of stamping problems, often resulting in shutdown, affecting the production cycle. Therefore, we must find the cause of the mold failure as soon as possible, reasonable maintenance.

1.Mold Damage

Mold damage refers to the mold cracking, breaking, opening, etc., to deal with mold damage, must be from the mold design, manufacturing process and mold use to find the reasons. First of all to check the mold manufacturing materials is appropriate, the corresponding thermal burial process is reasonable. In general, the heat treatment process of the mold material has a great influence on it. If the mold quenching temperature is too high, quenching methods and time unreasonable, as well as the number of tempering and temperature, elbow selection between the wrong, will lead to mold into the stamping after the production damage. Filling hole size or depth design is not enough, easy to block the hole, resulting in damage to the blanket plate. If the spring force is too small or the contour is not so high, it will cause the spring to break and the blanking plate is tilted, causing the overlap to hit and damage the parts.

The punch is not fixed or the screw is not strong enough to cause the punch to fall or break.

When the mold is used, parts are installed in the wrong direction or direction. Work height adjustment is too low, the guide column lubrication is insufficient. Feeding equipment failure, press abnormalities, etc., will cause damage to the mold. If there is foreign body into the mold, parts overlap, waste blockage and other conditions are not dealt with in time to continue processing production, it is easy to damage the blanking of the blank, punch, the next template and guide column.

2.Mold Stuck

Stamping process, once the die mold is not flexible, or even stuck, it must immediately stop production, find out the card model, troubleshooting. Otherwise, will expand the failure, resulting in mold damage.

The main reasons for the card mold are: poor mold orientation, tilt. Or between the template foreign body, so that the template can not be flat; mold strength design is not enough or uneven force. Resulting in mold deformation, such as mold base, the hardness of the template, the thickness of the design is too small, vulnerable to external impact deformation; mold location installation is not allowed, the upper and lower mold positioning error tolerance. Or the accuracy of the press is too poor, so that the mold interference; punch strength is not enough, the size of the punch too close, so that the lateral force of the mold imbalance. At this time should improve the punch strength, enhance the guidance of the discharge plate protection.

3. Mold Damage And Repair

Stamping production of high cost of molds. Usually the cost of the total cost of the workpiece 1 / 5-1 / 4. This is because, in addition to mold manufacturing difficult, high cost Put into production after the mold repair and grinding maintenance costs are high, while the original mold cost only about 40% of the cost of the mold. Therefore, timely maintenance of molds to prevent damage to the mold, can greatly reduce the stamping die production costs.

In general, after the mold is damaged, there is a maintenance and scrapping option. Non-natural wear failure of stamping dies, such as the destruction of non-critical parts. As well as small punch broken, punch upsetting shorter, concave mold plate cracking, punching edge crack, etc. Most of the maintenance method can be completely restored to normal state, re-put into the stamping production. but. When the key parts of the mold seriously damaged, sometimes convex, die at the same time damage. One-time repair costs more than 70% of the original cost of the die, or die life is near. The maintenance of the meaning is not, then you should consider scrapping mold: In addition to large-scale mold, the structure of a complex continuous die. When the mold repair technology is too complex, repair costs too much, the difficulty will inevitably make the maintenance cycle is too long, seriously affect the normal production stamping, should be selected ahead of schedule scrapped, re-manufacturing mold.

Stamping production efficiency and cost dependence on the mold is very large. The production process of mold failure, specific problems should be specific analysis, develop the correct maintenance program. Timely to solve the mold damage, card mold, grinding and product quality defects and other issues. To deal with the relationship between mold maintenance and scrap, in order to reduce the time to repair mold, shorten the production cycle, to ensure the normal production of stamping.